you are in: photo > digest > gyrobus

Gyrobus: a great idea takes a spin

It often takes courageous thinkers to re-assess a technical problem and come up with a new solution that is in fact a combination of existing principles (after all, there are only so many laws of physics). Some such solutions go onto to become the transport of the future, while others may fail because they don't present the hoped-for advantages or maybe run into otherwise unforseen problems. Nevertheless, such attempts should not be forgotten, as the time may come, when under a somewhat changed set of circumstances, they may yet find their niche or even rise to greater success.

It often takes courageous thinkers to re-assess a technical problem and come up with a new solution that is in fact a combination of existing principles (after all, there are only so many laws of physics). Some such solutions go onto to become the transport of the future, while others may fail because they don't present the hoped-for advantages or maybe run into otherwise unforseen problems. Nevertheless, such attempts should not be forgotten, as the time may come, when under a somewhat changed set of circumstances, they may yet find their niche or even rise to greater success.

The Gyrobus was conceived in post-war Switzerland. Motor buses at the time were still loud, uncomfortable and unreliable. The push for electric traction should also be seen, however, as part of the desire to strengthen the country's autonomy in the energy sector.  The First World War had been an important factor in deciding to implement large-scale electrification of railways. In the meantime, many cities had also established trolleybus systems, and at least in the public transport sector, domestic hydro-power was helping minimise coal and oil imports. Yet when the Second World War broke out, fuel had to be rationed and transport was again affected. More elecrification was required, but there were many services whose ridership were too light to justify a tram or trolleybus service. How could these routes best be served?

The First World War had been an important factor in deciding to implement large-scale electrification of railways. In the meantime, many cities had also established trolleybus systems, and at least in the public transport sector, domestic hydro-power was helping minimise coal and oil imports. Yet when the Second World War broke out, fuel had to be rationed and transport was again affected. More elecrification was required, but there were many services whose ridership were too light to justify a tram or trolleybus service. How could these routes best be served?

The Gyrobus was the brainchild of MFO's (Maschinenfabrik Oerlikon) chief engineer Bjarne Storsand, under whose leadership a flywheel energy storage system for traction was patented in 1946. The objective was to deploy this flywheel in vehicles with a small working range such as industrial and mining locomotives. However, there was one application that captured far more attention than any of these: a flywheel-powered bus.

Technical description

The Gyrobus prototype was built on the massive chassis of an FBW lorry dating from 1932. The flywheel (MFO called it the gyro) was positioned in the centre of this chassis between the axles. This disc weighing 1.5t and with a diameter of 1.6m was enclosed in an airtight chamber filled with hydrogen gas at a reduced pressure of 0.7 bar to lower "air" resistance. The flywheel would spin at a maximum of 3000rpm.

The Gyrobus prototype was built on the massive chassis of an FBW lorry dating from 1932. The flywheel (MFO called it the gyro) was positioned in the centre of this chassis between the axles. This disc weighing 1.5t and with a diameter of 1.6m was enclosed in an airtight chamber filled with hydrogen gas at a reduced pressure of 0.7 bar to lower "air" resistance. The flywheel would spin at a maximum of 3000rpm.

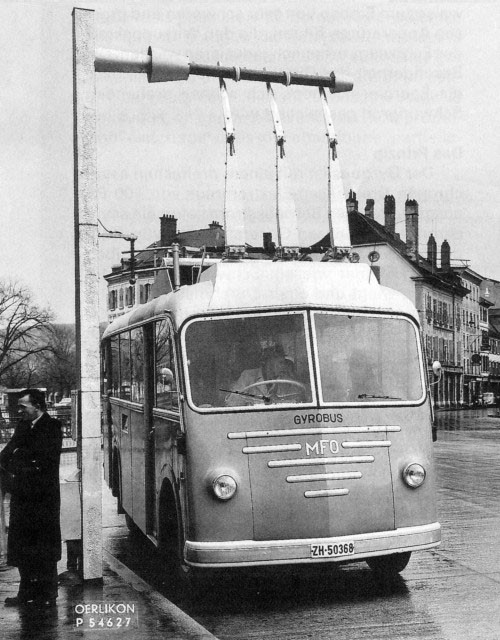

The principle of operation would be that the bus would "dock" into an overhead gantry located at selected stops. Contact blades would automatically rise and deliver three phase electricity to the flywheel at 380V. This choice of voltage permitted the normal mains power suppy to be used, so minimising the technical installations required. The flywheel could equally be charged by plugging it into a socket. This was the usual charging procedure at depots.

The flywheel was spun up with a three-phase asynchronous motor. The same motor acted as a generator when disconnected from the ground supply. The choice of an asynchronous brushless machine helped reduce friction within the flywheel assembly to an absolute minimum. Once in generator mode, power from the flywheel would be fed to the 52kW asynchronous traction motor, which was arranged longitudinally behind the rear axle. Capacitors controlled the motor torque. The arrangement could be reversed, with energy recovered by the motor during braking or on downhill runs being fed back to the flywheel.

In normal operation the flywheel could slow down from its initial 3000 rpm to 2100 rpm. In emergencies the speed could further be reduced to 1500 rpm, but this would negatively affect the performance of the vehicle. Below this speed a proper functioning of the transmission could no longer be guaranteed. Under normal conditions, the Gyrobus could cover 5 to 6km between charges (taking stops and traffic into account). A charge would then take two to five minutes. In idle mode, the fywheel could continue spinning for more than ten hours. The bus would, however, be plugged in at the depot overnight to keep the flywheel at 2850 rpm. This was done to permit a quick start in the morning and also because a full recharge would have posed a heavy load on the grid, A recharge from standstill could take 40 minutes. The bus could run at up to 55km/h.

The prototype

The prototype chassis was bodied by Carrosserie-Werken Aarburg (CWA). Early tests were performed at various locations around Zürich. The Gyrobus first appeared in public service on VBZ routes in 1950. Among others, the bus provided the Seeabch to airport service attracting much media attention. It was also demonstrated in other towns including Altdorf — Flüelen, Yverdon, Aarau, Heerbrugg — Hohenems, Locarno and München.

The prototype chassis was bodied by Carrosserie-Werken Aarburg (CWA). Early tests were performed at various locations around Zürich. The Gyrobus first appeared in public service on VBZ routes in 1950. Among others, the bus provided the Seeabch to airport service attracting much media attention. It was also demonstrated in other towns including Altdorf — Flüelen, Yverdon, Aarau, Heerbrugg — Hohenems, Locarno and München.

Although Zürich's VBZ showed great interest in the vehicle, no orders were placed. This was justified by not wishing to have a fourth mode besides its existing trams, trolleybuses and buses. For electric traction to the airport, the wheel has turned full circle however, as a tram – the Glattalbahn – will open on that route at the end of 2008.

Yverdon

The first order was placed by a private company in Yverdon. The Societé aonyme Gyrobus Yverdon — Grandson (GYG) inauguarted a bus service between those two places in 1953 using a fleet of two Gyrobuses, numbered 1 and 2. Like the prototype, these used a chassis by FBW, a body by CWA, and electrics by MFO. In contrast to the prototype, however, the chassis was purpose-designed for Gyrobus use, and weight savings were achieved. In keeping with the times, an angular body style was adopted. The route was 4.5km long and had four recharging points. In order to speed-up the charging process, the charging voltage was raised from 380V to 500V in 1954. The small fleet was joined by the prototype that year, with the new arrival being numbered 3.

The first order was placed by a private company in Yverdon. The Societé aonyme Gyrobus Yverdon — Grandson (GYG) inauguarted a bus service between those two places in 1953 using a fleet of two Gyrobuses, numbered 1 and 2. Like the prototype, these used a chassis by FBW, a body by CWA, and electrics by MFO. In contrast to the prototype, however, the chassis was purpose-designed for Gyrobus use, and weight savings were achieved. In keeping with the times, an angular body style was adopted. The route was 4.5km long and had four recharging points. In order to speed-up the charging process, the charging voltage was raised from 380V to 500V in 1954. The small fleet was joined by the prototype that year, with the new arrival being numbered 3.

The extremely light loadings of the route caused financial difficulties and led to service cuts. Rather than turing the company's fortunes around, these led to even greater difficulties. The high electricity consumption and other costs led GYG to replace its Gyrobuses by diesel minibuses in 1960.

Léopoldville

The next order came from Léopoldville in the Belgian Congo (today Kinshasa in D.R. Congo). The 12 buses ordered were largely similar to those of Yverdon and were numbered 101-112. The operator, Société: des transports en commun de Léopoldville (TCL) used them on a four-route system of about 20km, making it the largest Gyrobus system ever operated. However poor operating conditions and the tendency for drivers to deviate from the official routes and drive on rough unmade roads lead to heavy wear and tear. Consequently, TCL made generous use of its warranty rights with MFO to obtain spare parts. The outbreak of war in 1959 finally put an end to Gyrobus operations in Léopoldville.

The next order came from Léopoldville in the Belgian Congo (today Kinshasa in D.R. Congo). The 12 buses ordered were largely similar to those of Yverdon and were numbered 101-112. The operator, Société: des transports en commun de Léopoldville (TCL) used them on a four-route system of about 20km, making it the largest Gyrobus system ever operated. However poor operating conditions and the tendency for drivers to deviate from the official routes and drive on rough unmade roads lead to heavy wear and tear. Consequently, TCL made generous use of its warranty rights with MFO to obtain spare parts. The outbreak of war in 1959 finally put an end to Gyrobus operations in Léopoldville.

Gent

The third operator to acquire Gyrobuses was the Belgian SNCV/NMVB. Three buses numbered G1 to G3 (later 1451-3) were supplied by the usual consortium, but presented a more rounded front-end, maybe more in line with Belgian tatses. The Gent — Merelbeke service replaced a tram line in 1956. This line was and remained an island operation. It was especially the high costs of electricity that led to abandonment in 1959. One vehicle has survived and is preserved in the tram museum in Antwerpen. This vehicle, the only know Gyrobus survivor, visited Yverdon in 2003 to mark the 50th anniversary of that system.

The third operator to acquire Gyrobuses was the Belgian SNCV/NMVB. Three buses numbered G1 to G3 (later 1451-3) were supplied by the usual consortium, but presented a more rounded front-end, maybe more in line with Belgian tatses. The Gent — Merelbeke service replaced a tram line in 1956. This line was and remained an island operation. It was especially the high costs of electricity that led to abandonment in 1959. One vehicle has survived and is preserved in the tram museum in Antwerpen. This vehicle, the only know Gyrobus survivor, visited Yverdon in 2003 to mark the 50th anniversary of that system.

Other gyro applications

Besides these Gyrobuses, it should be noted that similar flywheels by MFO found use on various mining locomotives in Switzerland, Belgium and in Africa.

The Gyrobus: What went wrong?

One of the main obstacles facing the Gyrobus was its inability to gain a firm market presence and so cut down manufacturing costs through economy of scale. A further recurring issue was the high cost of electricity (or shall we say low cost of fuel). Furthermore, the manufacturers would appear to have been unfortunate in their choice of pilot projects, with many of the problems being external rather than strictly technical. Not necessarily a disadvantage but certainly a point worth noting was the dynamic behaviour of the vehicle. The spinning flywheel acts like a giant gyroscope and so resists changes in orientation. This had to be taken into account be the driver and so induced an adapted driving technique. At the same time, this gyroscope effect led to a very smooth ride. As reduced comfort through eratic driving is precisely an argument that is often used against buses, this is certainly something worth looking into

One of the main obstacles facing the Gyrobus was its inability to gain a firm market presence and so cut down manufacturing costs through economy of scale. A further recurring issue was the high cost of electricity (or shall we say low cost of fuel). Furthermore, the manufacturers would appear to have been unfortunate in their choice of pilot projects, with many of the problems being external rather than strictly technical. Not necessarily a disadvantage but certainly a point worth noting was the dynamic behaviour of the vehicle. The spinning flywheel acts like a giant gyroscope and so resists changes in orientation. This had to be taken into account be the driver and so induced an adapted driving technique. At the same time, this gyroscope effect led to a very smooth ride. As reduced comfort through eratic driving is precisely an argument that is often used against buses, this is certainly something worth looking into

In today's environment, many of the factors that disadvantaged the Gyrobus have changed. Fuel prices are rising and concerns over pollution and smog have led to experiments with such inefficient and dangerous storage technologies as hydrogen cells (which appear to be more in political favour than technologically sound). Would a simpler, safer and more comfortable alternative not do the same in a friendlier manner? Modern power electronics would help reduce power consumption whilst also enabling faster charging. Modern materials could help reduce the overall weight of the bus while retaining the required robustness. Maybe the Gyrobus is far from dead.

Sources

Copex, J.P., Le gyrobus d'Yverdon fête ses 50 ans, Tram magazine, No76/12.2003-02.2004, pp34-46.

Kamm, P., Der Trolleybus in Zürich, Verein Tram Museum Zürich, 2008, pp162-167.

view photos

Zürich tram newslog | Zürich trolleybus page

This page added: July 2008